Chiller System vs. VRF System

Chiller System vs. VRF System: Choosing the Right HVAC Solution for Your Building

In commercial and industrial HVAC systems, two popular options stand out: chiller systems and VRF (Variable Refrigerant Flow) systems. Both offer unique advantages and cater to different needs, making the decision between them crucial for building owners and managers. Let’s explore the key differences between these systems and determine which one might be the perfect fit for your clients’ needs.

Chiller System: Reliable Cooling Powerhouse

Chiller systems have long been the workhorses of large-scale cooling applications, offering reliable and efficient cooling solutions for buildings of all sizes. These systems operate by chilling water or a secondary refrigerant and circulating it through a network of pipes to cool indoor spaces. Here are some reasons why chiller systems remain a top choice for many clients:

- Proven Performance: Chiller systems have a track record of proven performance in providing consistent and reliable cooling even in the most demanding environments. Their robust design and ability to handle high cooling loads make them ideal for large commercial buildings, industrial facilities, and critical infrastructure such as data centers.

- Energy Efficiency: Despite their size and power, modern chiller systems are highly energy-efficient, thanks to advancements in compressor technology, variable speed drives, and intelligent controls. By optimizing energy usage and minimizing waste, chiller systems can help clients reduce operating costs and achieve sustainability goals.

- Longevity and Durability: Chiller systems are built to last, with components designed for durability and reliability. With proper maintenance and servicing, these systems can provide years of trouble-free operation, offering clients peace of mind and a solid return on investment.

VRF System: Flexible Zoning and Energy Savings

On the other hand, VRF systems offer a more decentralized approach to HVAC, allowing for individual zone control and greater flexibility in heating and cooling operations. These systems use a single outdoor condensing unit to connect multiple indoor fan coil units, each serving a specific zone or area within the building. Here’s why VRF systems might be the perfect choice for certain clients:

- Zoning Flexibility: VRF systems excel in applications where zoning flexibility is paramount. By independently controlling the refrigerant flow to each indoor unit, these systems can maintain different temperatures in various zones simultaneously, optimizing comfort and energy efficiency.

- Space-saving Design: VRF systems require minimal ductwork, making them ideal for retrofit projects or buildings with limited space for HVAC equipment. Their compact size and modular design allow for easier installation and reduced construction costs, particularly in urban or high-rise buildings.

- Energy Efficiency: VRF systems are inherently energy-efficient, thanks to their variable-speed compressors and precise temperature control capabilities. By matching cooling and heating output to the actual load requirements of each zone, VRF systems minimize energy waste and help clients achieve lower utility bills.

Choosing the Right System

Ultimately, the choice between a chiller system and a VRF system depends on various factors, including the size and layout of the building, cooling, and heating requirements, budget considerations, and client preferences. While chiller systems offer unparalleled reliability and performance for large-scale applications with so many application fields (Industry, manufacturing facility, cooling equipment, etc), VRF systems provide greater flexibility and efficiency in zoning and energy management and limited application fields.

As HVAC professionals, it’s essential to assess each client’s unique needs and tailor the HVAC solution accordingly. By understanding the benefits and trade-offs of both chiller systems and VRF systems, you can help your clients make informed decisions and ensure the optimal comfort and efficiency of their buildings.

In conclusion, whether it’s the robust reliability of a chiller system or the flexible zoning capabilities of a VRF system, there’s a perfect HVAC solution out there for every client.

Guide to Understanding Air Conditioning Systems

The Ultimate Guide to Understanding Air Conditioning Systems: From Regular Units to Chiller-Driven Central Cooling

Air conditioning (AC) systems are indispensable in providing comfort and maintaining the right temperature, regardless of the weather outside. From compact window units in our homes to sophisticated chiller-driven central cooling systems in large complexes, the technology behind these systems is fascinating and complex. This guide aims to demystify the world of air conditioning, exploring the nuances of regular AC systems and the intricacies of chiller-driven central cooling systems.

Navigating the World of Regular AC Systems

Regular AC systems, or Direct Expansion (DX) Systems, are the backbone of residential and small commercial building cooling solutions. They employ a straightforward refrigeration cycle, directly cooling the indoor air with refrigerant. Let’s explore the different types of regular AC systems:

Window Units: The Compact Cooling Solution

What Are They? Window units are self-contained air conditioning systems that fit snugly into window frames. They are the go-to solution for cooling single rooms or small spaces efficiently.

Visual Guide: These units are typically box-shaped, with a front panel with controls and an air outlet. The rest of the unit extends outside to expel heat, designed to be discreet and blend seamlessly with window frames.

Split Systems: The Versatile Cooling Companion

What Are They?

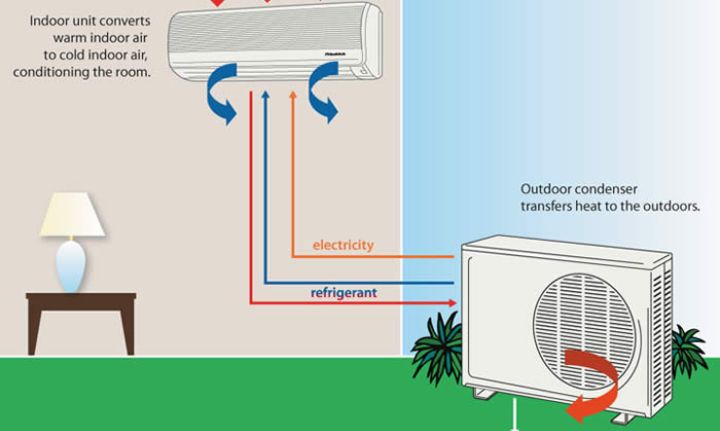

Named for their split configuration, these systems consist of an outdoor unit (housing the compressor and condenser) and one or more indoor units (containing evaporators), connected by refrigerant lines.

Visual Guide:

Outdoor Unit: This is usually a rectangular box situated on the ground or mounted on an exterior wall, featuring a fan to dissipate heat.

Indoor Units: Options include wall-mounted, ceiling-mounted, or floor-standing units, chosen based on space and aesthetic preferences. Wall-mounted variants are particularly popular for their sleek, modern appearance.

Packaged Units: The All-in-One Cooling Powerhouse

What Are They?

These systems consolidate most AC components into one unit, often placed outdoors on rooftops or beside buildings. They cater to the cooling needs of small to medium-sized commercial buildings.

Visual Guide: Packaged units are bulkier and more industrial-looking than their window or split system counterparts, designed with functionality and easy maintenance in mind.

Exploring Chiller-Driven Central Cooling Systems

Chiller-driven central cooling systems are the standard for larger buildings or complexes with high cooling demands, such as office buildings, shopping centres, and industrial facilities. These systems chill water to cool the air, offering a highly efficient cooling solution.

Chillers: The Heart of Central Cooling

What Are They?

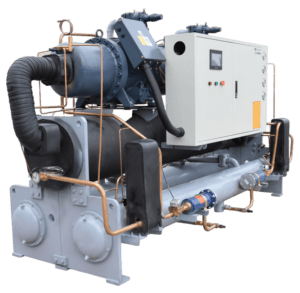

Chillers are central to these cooling systems, tasked with producing chilled water. They can be air-cooled or water-cooled, with water-cooled variants being more efficient but requiring additional infrastructure.

Visual Guide: Typically large and either cylindrical or rectangular, chillers are equipped with a complex network of pipes and valves. Due to their industrial aesthetics, they are usually placed in mechanical rooms or rooftops, away from public view.

Cooling Towers: The Unsung Heroes for Water-Cooled Systems

What Are They?

Essential in water-cooled systems, cooling towers help expel heat from the system’s water to the outside air. They allow some water to evaporate, effectively removing heat from the system.

Visual Guide: These are large, tower-like structures with a distinctive design that narrows from a wide base towards the top. Constructed from materials like metal or fibreglass, they’re often seen emitting steam on hot days.

Air Handling Units (AHUs): Distributing Comfort

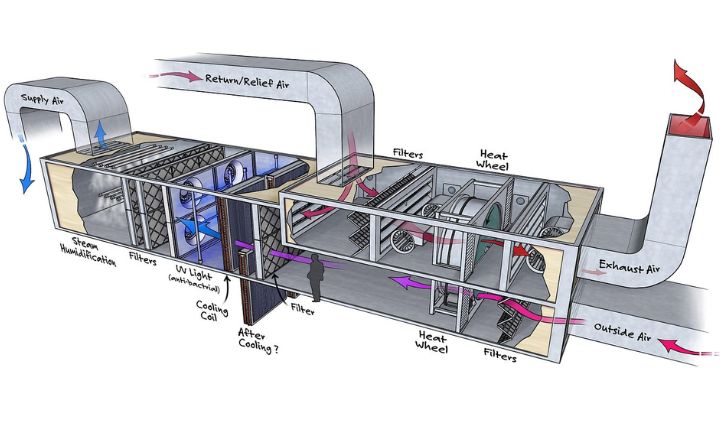

What Are They?

AHUs are critical in circulating and conditioning air using chilled water from the chillers. They are key to distributing cooled air throughout the building.

Visual Guide: Situated within the building, AHUs are sizable metal boxes connected to the ductwork. Their size varies based on the cooling requirements of the building but is generally concealed in mechanical rooms or above ceilings.

This comprehensive guide sheds light on the diverse world of air conditioning systems, from the simplicity of regular AC units to the complexity of chiller-driven central cooling systems. Understanding these systems enhances our appreciation for modern cooling solutions and informs our choices, ensuring we select the most efficient and suitable options for our spaces.

Chillers & Heat Pumps A Game-Changer for Indoor Fish Farming

Recently, indoor fish farming has emerged as a sustainable solution to meet the growing seafood demand while reducing environmental impact. Water temperature regulation is key to indoor aquaculture’s success. No matter whether the farm uses saltwater or freshwater, chillers, and heat pumps come in handy.

The Importance of Temperature Control

The temperature of the water must be maintained at an optimal level to maintain the health and growth of aquatic species. The fish may be stressed by fluctuations outside the ideal range, which weakens their immune systems and hinders their growth. Temperature fluctuations in extreme cases may trigger mass mortality events, jeopardizing the operation in its entirety.

A chiller plays a crucial role in indoor fish farming, particularly in systems that require cooler water temperatures. A chiller provides precise cooling to maintain a stable aquatic environment regardless of whether cold-water species like trout or salmon are being cultivated or the temperature is just being regulated during warm seasons.

By removing heat from the water, these refrigeration units reduce its temperature. During times of high external temperatures, chillers help maintain optimal conditions by circulating chilled water through fish tanks or recirculating aquaculture systems (RAS). It is particularly useful in areas where there are significant temperature fluctuations or in areas where the availability of natural water sources is limited.

Alternatively, some indoor fish farming operations require warmer water temperatures, particularly for species native to tropical or subtropical regions. In such cases, heat pumps offer an energy-efficient solution by extracting heat from the surrounding environment and transferring it to the water.

As a result of their ability to raise the water temperature, heat pumps utilize compressors and refrigerants to work on the principle of thermodynamic heat exchange. Not only is this technology environmentally friendly, but it is also cost-effective, as it significantly reduces energy consumption.

Versatility Across Saltwater and Freshwater Systems

Chillers and heat pumps are remarkable for their versatility in both freshwater and saltwater environments. These temperature control systems can be tailored to meet the specific requirements of different species of fish, whether they are cultivating marine species like shrimp, and tilapia, or freshwater species like catfish or carp.

Saltwater systems require chillers that are built from corrosion-resistant materials to ensure their durability and longevity. Similarly, heat pumps designed to withstand the corrosive nature of seawater provide reliable heating solutions for marine and aquaculture operations.

These technologies can be used in freshwater setups to regulate water temperature efficiently without compromising the water’s quality or the fish’s health. The ability to customize settings and control temperature accurately allows indoor fish farmers to create optimal conditions for different species, thereby promoting faster growth and higher yields.

Conclusion

A combination of chillers and heat pumps has revolutionized indoor fish farming, allowing for unprecedented control over water temperatures, regardless of the aquatic environment. From freshwater to tropical fish, these technologies ensure optimal growth, health, and sustainability.

As the demand for seafood continues to rise and environmental concerns mount, the integration of chillers and heat pumps in indoor aquaculture represents a significant step towards meeting global food security needs while minimizing ecological impact. With ongoing advancements in technology and a commitment to innovation, the future of indoor fish farming looks promising, thanks to these indispensable temperature control solutions.

Check out a video on indoor fish farming where kaydeli supplied chillers.

How to Properly install cooling tower for water cooled chiller

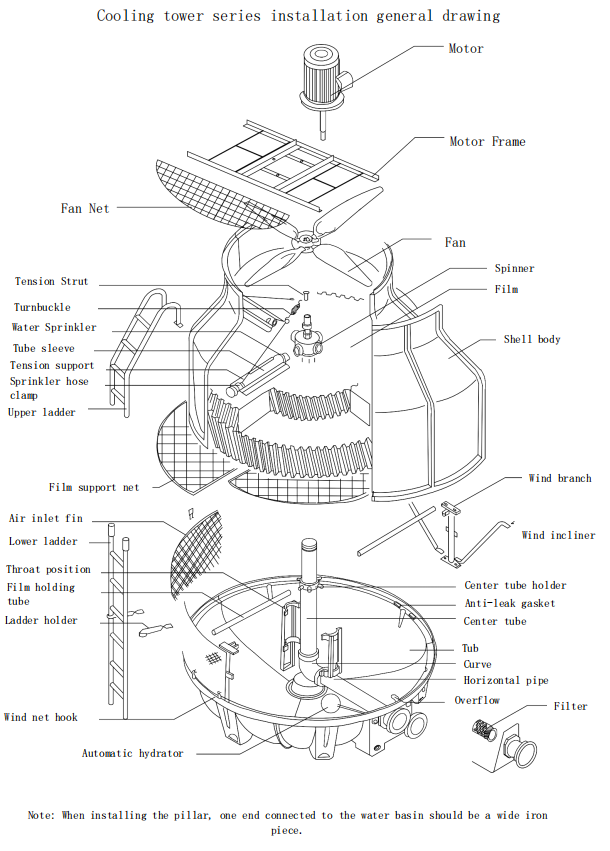

Installing a cooling tower is essential for optimizing the cooling performance of a water-cooled chiller, especially in industrial and commercial settings.

Step 1: Selecting the Right Location

The first step in installing a cooling tower is to select the appropriate location. Ensure that the site is level, well-ventilated, and has easy access for maintenance. Additionally, consider factors such as noise levels and proximity to water sources.

Step 2: Foundation Preparation

Before installing the cooling tower, prepare a solid foundation to support its weight and ensure stability. The foundation should be level, reinforced, and capable of withstanding the load of the cooling tower and circulating water.

Step 3: Assembling the Cooling Tower

Begin by unpacking the cooling tower components and following the manufacturer’s instructions for assembly. Install the fan, fill media, drift eliminators, and other components according to the provided guidelines.

Step 4: Connecting Water Lines

Next, connect the water lines from the chiller to the cooling tower. Ensure that the piping is sized correctly, insulated, and supported to prevent leaks and optimize water flow between the chiller and cooling tower.

Step 5: Electrical Connections

Make electrical connections for the cooling tower fan motor and any other necessary components. Follow electrical codes and safety guidelines to ensure proper wiring and prevent electrical hazards.

Step 6: Testing and Commissioning

After completing the installation, thoroughly test the cooling tower system to ensure proper functionality. Check for leaks, monitor water flow, inspect electrical connections, and verify that the system is operating as intended.

Step 7: Maintenance and Monitoring

Consistent maintenance is vital to keep a cooling tower operating efficiently. Create a maintenance schedule that covers important tasks like cleaning the fill media, assessing water quality, detecting leaks, and monitoring system performance.

Conclusion

Installing a cooling tower for a water-cooled chiller is a critical step in maintaining optimal cooling efficiency for industrial and commercial applications. By following this step-by-step guide, you can ensure a successful installation process and maximize the performance of your cooling system.

Remember to consult with professionals or refer to manufacturer guidelines for specific instructions tailored to your cooling tower system. Proper installation and maintenance are vital to extending the lifespan of your equipment and ensuring consistent cooling performance. If still not very clear feel free to contact us.

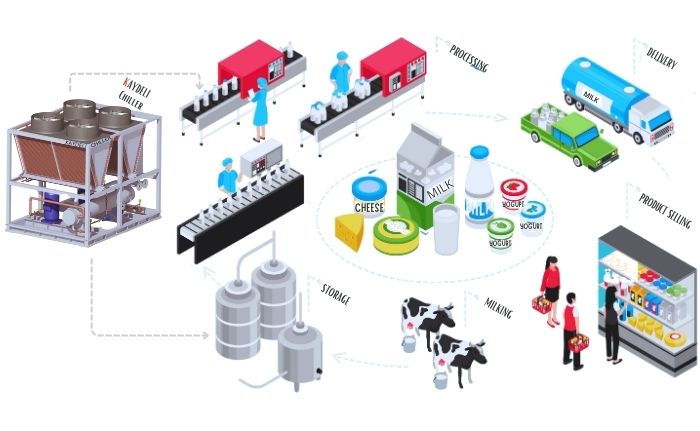

The Essential Role of Industrial Chillers in Dairy Process

Industrial chillers play a crucial role in the dairy industry, providing essential cooling solutions for various processes. From milk storage and processing to cheese production, industrial chillers are integral to maintaining the quality and safety of dairy products. As the demand for dairy products continues to grow, the reliance on efficient and reliable industrial chillers becomes increasingly significant.

Milk Processing and Storage

In the dairy industry, milk is a primary raw material that undergoes various processing stages before reaching consumers in the form of pasteurized milk, cheese, yogurt, ice cream, and other dairy products. Industrial chillers are essential for maintaining the freshness and quality of milk during processing and storage.

Pasteurization Process

One of the critical steps in milk processing is pasteurization, which involves heating the milk to eliminate harmful bacteria and pathogens. Following pasteurization, rapid cooling is necessary to reduce the milk’s temperature to safe storage levels. Industrial chillers facilitate this rapid cooling process, ensuring that the milk remains safe for consumption while preserving its nutritional value.

Cheese Production

Industrial chillers play a vital role in cheese production, where precise temperature control is essential for curd formation, whey separation, and the aging process. The consistency and quality of cheese greatly depend on maintaining specific temperature conditions throughout these stages. Industrial chillers provide the necessary cooling capacity to support these critical processes, enabling dairy manufacturers to produce high-quality cheeses consistently.

Yogurt and Dairy Desserts

For yogurt and other dairy desserts, maintaining a controlled and low temperature is essential during fermentation and storage. Industrial chillers are instrumental in creating optimal conditions for the fermentation process, which directly impacts the taste, texture, and shelf life of yogurt and dairy desserts. Additionally, industrial chillers contribute to extending the shelf life of these products by ensuring proper storage temperatures are maintained throughout the distribution chain.

Environmental Control

Beyond specific dairy product processing, industrial chillers also contribute to environmental control in dairy facilities. They help regulate temperatures in various areas such as cold storage rooms, production areas, and packaging facilities. This environmental control is crucial for preserving the overall quality of dairy products and ensuring compliance with food safety standards.

Energy Efficiency and Sustainability

With an increasing focus on sustainability and energy efficiency, modern industrial chillers are designed to minimize energy consumption while delivering optimal cooling performance. By investing in energy-efficient industrial chillers, dairy manufacturers can reduce operational costs and minimize their environmental impact. Additionally, some industrial chillers utilize eco-friendly refrigerants, further aligning with sustainable practices in the dairy industry.

Conclusion

In conclusion, industrial chillers are indispensable in the dairy industry, supporting a wide range of processes from milk processing and storage to cheese production and environmental control. Their role in maintaining precise temperatures, ensuring food safety, and enhancing energy efficiency underscores their significance in the production of high-quality dairy products. As the dairy industry continues to evolve, the demand for advanced industrial chillers that offer superior performance and sustainability will remain essential for meeting consumer demands while upholding industry standards. Contact Kaydeli to get a consultation about dairy process chillers.

Chillers in Textile Industry: Importance & Function

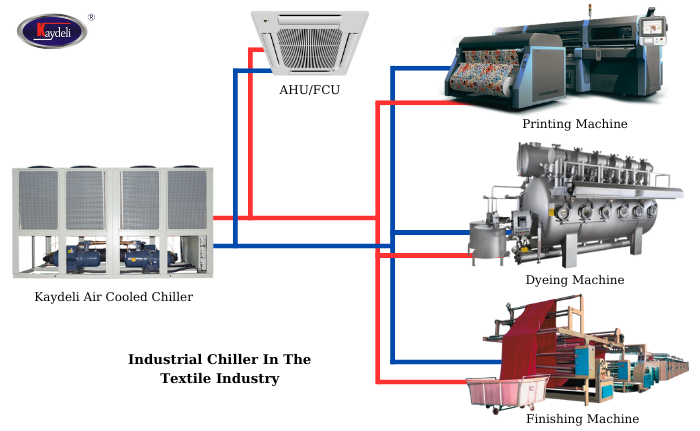

In the textile industry, industrial chillers play a crucial role in ensuring high-quality products. These machines are responsible for cooling water used in various textile processes such as dyeing, printing, and finishing. In this article, we will explore how industrial chillers work and their importance in the textile industry.

How Industrial Chillers Work

Industrial chillers are designed to remove heat from a liquid or gas in a closed-loop system. They use a refrigeration cycle to cool water, which is then circulated through the textile production process. The refrigeration cycle works by compressing a refrigerant gas, which raises its temperature. The hot gas is then cooled and condensed back into a liquid, releasing heat in the process. The liquid refrigerant is then expanded, causing it to cool down significantly. This cold liquid is then used to cool the water in the textile production process.

There are two types of industrial chillers: air-cooled and water-cooled. Air-cooled chillers use ambient air to cool the refrigerant, while water-cooled chillers use water to cool the refrigerant. Water-cooled chillers are more efficient than air-cooled chillers, but they require a constant supply of water.

Importance of Industrial Chillers in the Textile Industry

Industrial chillers play a critical role in the textile industry by ensuring that water used in various processes is at the right temperature. Here are some of the reasons why industrial chillers are important in the textile industry:

Dyeing

Dyeing is the process of adding color to textiles. This process requires hot water to be circulated through the fabric to ensure that the dye penetrates evenly. Industrial chillers are used to cool down the water after it has been heated to the required temperature. This ensures that the fabric is not damaged and that the dye penetrates evenly.

Printing

Printing is the process of adding designs or patterns to textiles. This process requires hot water to be circulated through the fabric to ensure that the ink adheres properly. Industrial chillers are used to cool down the water after it has been heated to the required temperature. This ensures that the fabric is not damaged and that the ink adheres properly.

Finishing

Finishing is the process of improving the appearance and texture of textiles. This process requires hot water to be circulated through the fabric to ensure that it is properly finished. Industrial chillers are used to cool down the water after it has been heated to the required temperature. This ensures that the fabric is not damaged and that it is properly finished.

Energy Efficiency

Industrial chillers are designed to be energy efficient. They use less energy than traditional cooling methods such as air conditioning. This means that they can help textile manufacturers save money on their energy bills.

Product Quality

Industrial chillers help ensure that textile products are of high quality. By maintaining a consistent temperature throughout the production process, industrial chillers help prevent damage to fabrics and ensure that dyes, inks, and finishes adhere properly.

Conclusion

Industrial chillers play a critical role in ensuring high-quality textile products. They help maintain a consistent temperature throughout the production process, preventing damage to fabrics and ensuring that dyes, inks, and finishes adhere properly. Industrial chillers are also energy efficient, helping textile manufacturers save money on their energy bills.

Why Chillers are Vital for Hydrogen Infrastructure

The Importance of Industrial Chillers in Hydrogen Station Systems

As the world shifts towards cleaner energy sources, hydrogen fuel is becoming an increasingly popular alternative to traditional fossil fuels. Hydrogen fuel cell vehicles are already on the roads, and the infrastructure to support them is rapidly expanding. One key component of this infrastructure is the hydrogen refueling station, which uses industrial chillers to cool and compress hydrogen gas for storage and dispensing.

What is an Industrial Chiller?

An industrial chiller is a piece of equipment that uses refrigeration technology to cool water or other fluids to a desired temperature. This chilled fluid can then be used to cool other equipment or processes. Industrial chillers come in a variety of sizes and configurations, depending on the specific application.

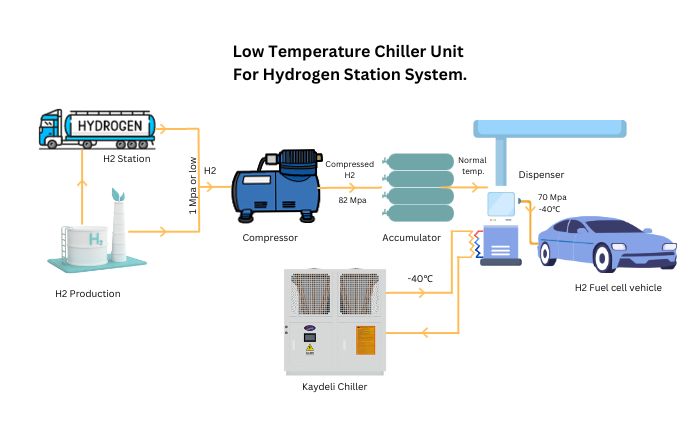

How Does an Industrial Chiller Work in a Hydrogen Station System?

In a hydrogen station system, an industrial chiller is used to cool and compress hydrogen gas. When hydrogen is produced, it is typically at a high temperature and pressure. To store and dispense the hydrogen safely, it must be cooled and compressed to a lower temperature and higher pressure.

The process begins with the hydrogen gas being fed into the chiller. Inside the chiller, the gas is cooled by a heat exchanger that uses chilled water or another cooling fluid. As the gas is cooled, it condenses into a liquid, which is then compressed by a pump to increase its pressure.

The compressed liquid hydrogen is then stored in high-pressure tanks until it is needed for refueling. When a vehicle pulls up to the refueling station, the liquid hydrogen is dispensed into the vehicle’s fuel tank, where it evaporates back into a gas and is used to power the vehicle’s fuel cell.

Why are Industrial Chillers Important in Hydrogen Station Systems?

Industrial chillers are a critical component of hydrogen station systems for several reasons. First, they are necessary to cool and compress the hydrogen gas for storage and dispensing. Without industrial chillers, it would be impossible to safely store and distribute hydrogen fuel.

Second, industrial chillers help to improve the efficiency of the hydrogen production process. By cooling the hydrogen gas before it is compressed, less energy is required to compress it to the desired pressure. This means that more of the energy from the original source (such as solar or wind power) can be used to produce hydrogen, rather than being lost as waste heat.

Finally, industrial chillers help to ensure the safety of hydrogen refueling stations. Hydrogen gas is highly flammable, and storing it at high pressures can be dangerous if not done correctly. By cooling and compressing the gas in a controlled manner, industrial chillers help to minimize the risk of accidents and ensure that refueling stations are safe for both customers and employees.

Types of Industrial Chillers Used in Hydrogen Station Systems

There are several types of industrial chillers that can be used in hydrogen station systems, depending on the specific requirements of the application. The most common types include:

Air-cooled chillers use ambient air to dissipate heat from the cooling fluid. They are typically less expensive and easier to maintain than water-cooled chillers, but they are less efficient and may not be suitable for applications where precise temperature control is required.

Water-cooled chillers use water to dissipate heat from the cooling fluid. They are generally more efficient than air-cooled chillers and can provide more precise temperature control, but they require a constant supply of water and may be more expensive to install and maintain.

Conclusion

Industrial chillers are a critical component of hydrogen station systems, enabling safe and efficient storage and dispensing of hydrogen fuel. By cooling and compressing the hydrogen gas, industrial chillers help to improve the efficiency of the production process while ensuring that refueling stations are safe for both customers and employees. With continued investment in clean energy infrastructure, industrial chillers will play an increasingly important role in supporting the transition to a more sustainable future.

Ice rink project for Guangdong province

The Power of an 80-Ton Water-Cooled Chiller

Introduction:

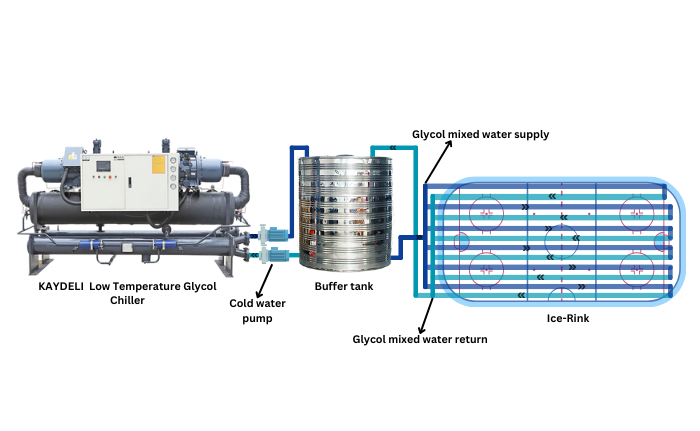

Ice skating is a popular recreational activity enjoyed by people of all ages. In Guangdong province, China, the construction of an ice rink presented a unique challenge due to the region’s warm climate. To overcome this obstacle, an 80-ton water-cooled chiller from KAYDELI was employed to maintain a constant temperature of -8℃. This article explores the critical role of the chiller, the use of a glycol mixture as a coolant, and the essential components required to create a typical ice rink.

The Chiller: A Key Player in Ice Rink Construction

The 80-ton water-cooled chiller emerged as the hero of the ice rink construction project. With its impressive cooling capacity (183.1kW at -10℃), it ensured that the required temperature of -8℃ was consistently maintained. As per our client’s requirement, we chose the water-cooled type which is more efficient in terms of cooling and low maintenance. By utilizing advanced cooling technology, the chiller effectively counteracted the warm climate of Guangdong province, creating an ideal environment for ice skating enthusiasts.

The Glycol Mixture: A Reliable Coolant

To achieve the desired temperature, a glycol mixture was selected as the coolant for the ice rink. Glycol, a type of antifreeze, possesses excellent thermal properties and prevents freezing at subzero temperatures. By circulating the glycol mixture through the piping system, the chiller efficiently transferred heat away from the ice surface, keeping it frozen and safe for skating.

Piping System: Supplying Coolant for Optimal Cooling

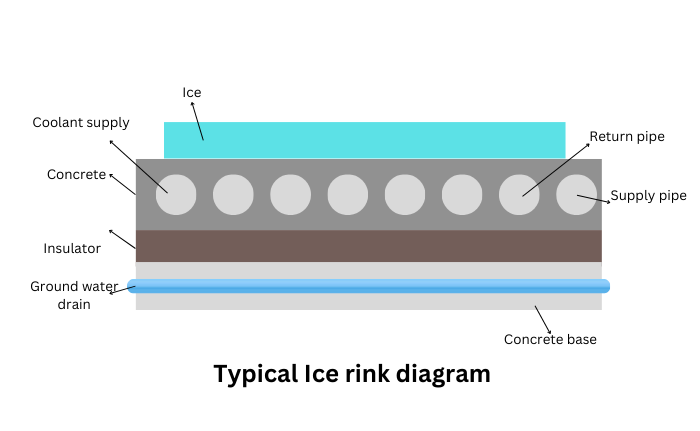

A well-designed piping system played a crucial role in supplying the glycol mixture throughout the ice rink. This system ensured that the coolant reached every corner of the rink, maintaining a uniform temperature across the entire surface. By strategically placing the pipes beneath the ice, the heat was rapidly dissipated, allowing for efficient cooling and preventing any potential melting.

Building the Foundation: The Base for an Ice Rink

Creating a solid foundation is essential for constructing an ice rink that can withstand heavy usage and provide a smooth skating experience. The base for an ice rink typically consists of multiple layers, including insulation, piping, and a concrete or asphalt surface. The insulation layer prevents heat transfer from below, while the piping system distributes the coolant evenly. Finally, a durable concrete or asphalt surface provides stability and support for skaters.

Conclusion:

Constructing an ice rink in Guangdong province presented unique challenges due to its warm climate. However, by leveraging advanced cooling technology and utilizing an 80-ton water-cooled chiller, a successful ice rink was built with a consistent temperature of -8℃. The glycol mixture served as an efficient coolant, circulating through a well-designed piping system to maintain optimal cooling across the entire surface. With these essential components in place, ice skating enthusiasts can now enjoy their favorite activity in Guangdong province throughout the year.

Heat pumps working principle in the greenhouse

A greenhouse is a valuable tool for any farmer or gardener looking to extend their growing season and protect their plants from harsh weather conditions. However, maintaining a consistent temperature inside a greenhouse can be a challenge, especially during extreme weather conditions. This is where a heat pump comes in handy.

A heat pump is an energy-efficient heating and cooling system that can be used to regulate the temperature inside a greenhouse. It works by extracting heat from the air or ground outside the greenhouse and transferring it inside to warm the space during the winter. During the summer, the heat pump can reverse the process and extract heat from inside the greenhouse and release it outside to cool the space.

One of the main benefits of using a heat pump in a greenhouse is that it can provide consistent temperature control throughout the year. This is important because plants require a specific temperature range to grow and thrive. If the temperature inside a greenhouse fluctuates too much, it can cause stress to the plants and even damage them. By using a heat pump, farmers and gardeners can ensure that their plants are kept at a consistent temperature, regardless of the weather conditions outside.

Another benefit of using a heat pump in a greenhouse is that it is an energy-efficient solution for heating and cooling. Heat pumps use electricity to transfer heat, rather than generating heat through combustion like traditional heating systems. This means that they can provide the same amount of heating or cooling with less energy, resulting in lower energy bills and reduced carbon emissions.

So how do heat pumps work for cooling and heating? There are two main types of heat pumps: air-source and ground-source. Air-source heat pumps work by extracting heat from the air outside the greenhouse and transferring it inside. They do this by using a refrigerant that absorbs heat from the air and then compresses it to increase its temperature. The heated refrigerant is then circulated through a coil inside the greenhouse, where it releases its heat to warm the space.

Ground-source heat pumps work in a similar way, but they extract heat from the ground instead of the air. They do this by using a loop of pipes buried underground that are filled with a water and antifreeze solution. The solution absorbs heat from the ground and is then pumped through a heat exchanger inside the greenhouse to warm the space.

Both types of heat pumps can also be used for cooling by reversing the process. Instead of extracting heat from outside or underground, they extract heat from inside the greenhouse and release it outside. This cools the space down to the desired temperature.

In summary, a greenhouse needs a heat pump to keep it warm during the winter and cool during the summer because it provides consistent temperature control and is an energy-efficient solution for heating and cooling. Heat pumps work by extracting heat from outside or underground and transferring it inside to warm the space, or extracting heat from inside and releasing it outside to cool the space. By using a heat pump, farmers and gardeners can ensure that their plants are kept at a consistent temperature throughout the year, resulting in healthier plants and higher yields.

How Glycol Chillers Works In The Brewing Industry

A glycol chiller is an essential component in the brewing industry as it helps maintain the ideal temperature for the brewing process. The brewing process involves a complex series of chemical reactions that are temperature-dependent. As such, it is crucial to keep the temperature within a specific range to ensure that the beer quality is consistent and of high quality.

Glycol chillers are used to regulate the temperature of the glycol solution, which is then circulated through the cooling jackets of the fermenters and bright tanks. The glycol solution absorbs the heat generated during fermentation and transfers it to the chiller, where it is expelled into the atmosphere. This process prevents the beer from overheating, which can lead to undesirable flavors and aromas.

Here is how it works:

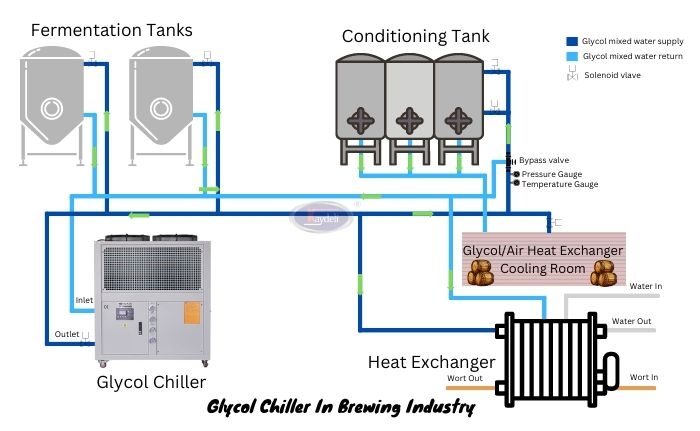

Glycol chillers work by circulating a glycol solution through a closed-loop system that includes fermentation tanks, conditioning tanks, and heat exchangers. The glycol solution absorbs the heat generated during the fermentation process and transfers it to the chiller, where it is expelled into the atmosphere.

The glycol solution is pumped through cooling jackets that surround the fermentation and conditioning tanks. As the glycol solution circulates through the jackets, it absorbs the heat generated by the yeast during fermentation. The heated glycol solution is then pumped back to the chiller, where it is cooled down before being recirculated through the cooling jackets.

Glycol chillers can also provide cooling for the storage room by circulating cool glycol solution through air handling units. This process helps maintain a consistent temperature in the storage room, preventing spoilage of the beer.

In addition to cooling the fermentation and conditioning tanks, glycol chillers can also be used in heat exchangers to chill the beer. The beer is passed through a heat exchanger that is cooled by the glycol solution. As the beer passes through the heat exchanger, it is rapidly cooled down to the desired temperature before being transferred to the conditioning tanks.

Glycol chillers are also used in other industries such as food processing, pharmaceuticals, and HVAC systems. In the food processing industry, glycol chillers are used to maintain the temperature of food products during production. For example, they are used to cool chocolate during the tempering process or to keep ice cream mixtures at a specific temperature during production.

In the pharmaceutical industry, glycol chillers are used to maintain the temperature of vaccines and other medications. Vaccines require strict temperature control during storage and transportation to ensure their efficacy. Glycol chillers are used to keep the vaccines at a specific temperature range to prevent degradation and ensure their effectiveness.

In HVAC systems, glycol chillers are used to cool water that is circulated through air handling units to regulate the temperature of a building. This process helps maintain a comfortable indoor environment for occupants.

In conclusion, glycol chillers are essential components in various industries, including the brewing industry. They help maintain the ideal temperature for different processes, ensuring consistent quality and preventing spoilage. Other industries such as food processing, pharmaceuticals, and HVAC systems also rely on glycol chillers for temperature regulation.